Silica (SiO2) is a group of minerals consisting of silicon and oxygen, and is divided into various groups size, shape and crystal structure. Consists of Silica Stone, Silica Granules, and Silica Sand

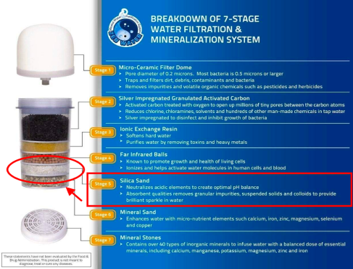

Various sizes Silica is useful as a raw material for the aggregate & instant cement industry, water filtration process (water treatment), processing industry, sand blasting, glass-making raw materials, as well as materials for making molds.

PT. Silica Nusantara Mineral is a business entity in the form of PT (Company Limited), Established in 2022 according to SK. Ministry of Law and Human Rights Number AHU-0066477.AH.01.01 Year 2012.

PT Silica Nusantara Mineral is a company engaged in quarrying, mining, processing and processing of silica sand (Quartz Sand).

Able to produce 50,000 tons per month quickly and ready to be shipped worldwide.

Has high quality Silica Sand, contains 99% Pure SIO2, Clean White, with low lime content.

Fully support citizen participation by accommodating and absorbing people's mining products.

To preserve the natural resource given by empowering people with integrity to achieve more by focusing on innovative solutions that maximize our returns to society with sincerity and hard-work.

Running a business with integrity, professional attitude & commitment through quality products and service support to satisfaction & trust consumers, and build good long-term and sustainable relationships.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Silica sand is a primary component in the manufacturing of glass. It is a very important raw material for standard and special glasses. The chemical purity of silica sand is the principal determinant of strength, colour and clarity. It is used to produce flat glass for building and automotive uses and for container glass that stores food and beverages. It reinforces glass fibres and required for the production of fibreglass insulation. It is applied in speciality glasses that include test tubes, scientific tools, television and CRT monitors, and also in incandescent and fluorescent lamps.

On synthetic sports fields and golf courses, silica sand is used for bunkers and greens. Because of its ability to support and natural plant growth, it is also used to maintain greens and fairways. The natural grained shape provides the required permeability and helps to facilitate day to day maintenance like root aeration and fertilization.

For manufacturing calcium silicate bricks, silica sand is mixed with high calcium lime with a sand to lime ratio of 10 or 20. These bricks contain good regularity, smooth faces, and sharp corners with a wide variety of strength. The durability of calcium silicate bricks is similar to concrete and is not resistant to sulphur- containing environments.

Silica sand is an effective filtration bed in the removal of contaminants in both processing of wastewater and in the filtration of the drinking water. Silica sand neutralizes the acidic elements to maintain optimal pH balance in water filters. As it is chemically inert, it will not react when exposed to acids, contaminants, volatile organics or solvents.

Silica sand is an essential part of the production of steel, ferrous and non-ferrous foundry industries for de-oxidation and grain refinement. For obtaining desired internal or external shapes, metal parts are cast in silica sand. It is a preferred choice for castings that involve cast iron, steel, titanium and also used to clean the casting surfaces.

Silica sand constitutes of high-performance properties such as brightness, reflectance, oil absorption and colour-consistency. These properties help to improve the overall appearance and durability of industrial and architectural paints and coatings. Its low oil absorption nature improves finishing colour that makes a durable coating rich in pigments. Silica fillers improve tint retention and also provide resistance to dirt, mildew, weathering and cracking.

It is the primary component in a variety of building and construction products. For improved durability and structural integrity, whole grain silica is used in flooring, mortars, specialty cement, roofing shingles, asphalt mixtures, skid-resistant surfaces and in other industrial materials. It performs as a functional extender to add durability, anti-corrosion and weathering properties in sealants, caulks, epoxy-based compounds.

Due to its round and angular varieties, it is commonly used as a mineral abrasive for industrial blasting. Silica sand helps in making the round surfaces smooth, used in sandblasting with using some resins that prevent from health hazards caused by silica dust.

We are able to increase production capacity as needed

Our silica sand is very good for use as a raw material for the glass industry, supporting material for the ceramic industry, light brick industry, cement industry, water treatment and other industries.

We are ready to increase our production capacity to serve shipments outside the area with a lot of demand.

Silica Sand

0.2 – 2 mm

Silica Homogen

> 2 mm

Silica 5.1

1 cm – 5 cm

Silica 5.14

5 cm – 14 cm ++